Hugo de Lasa

Contact

Department of Chemical and Biochemical Engineering

Claudette Mackay-Lassonde Pavilion,

Room CMLP 3331

Western University

Tel: 519-661-2111 ext. 82144

Fax: 519-661-3498

hdelasa@eng.uwo.ca

Publications

Prof. de Lasa’s activities have been of key importance for furthering the understanding of the science and the technology of chemical reactors. His original work deals with the application of chemical reactor engineering to environmentally friendly processes and products. Prof. de Lasa’s research innovations are being extensively documented in the open literature.

Publications Record

|

Number of Peer-Reviewed Articles Number of Peer-Reviewed Conference Proceedings |

261 |

|

Number of Book Chapters |

6 |

|

Number of Books |

1 |

|

Number of Patents |

14 |

|

Total Citations (Scopus) Total Citations (Google Academics) Total Citations (Research Gate) |

7336 7372 |

|

H-index (using Scopus) , H-Index (using Google) |

42 and 53 |

Most Cited Publications

- In 2005, H. de Lasa et al., published a book entitled Photocatalytic Reaction Engineering, which is a milestone in the literature on photocatalysis. As of today, it has been cited 449 times, as attested in Google Academics.

- The “Chemical Looping Combustion (CLC) for Inherent CO2 Separations- A Review”, by M. Hossain and de Lasa, published in Chemical Engineering Science, Vol.63, Issue 18, 4433-4451 (2008) (IF: 3.871) was one of the 2 most cited articles in Chemical Engineering Science, in the five years following publication. In May 2021, this article’s Google Citations were 1003.

- During the period of 2016-2020, Hugo de Lasa received the Special Mention from Research Gate for the “Most Cited Publications in the Department of Chemical and Biochemical Engineering - University of Western Ontario” as follows: a) 36 in December 2016, b) 43 in May 2016, c) 36 in December 2017, d) 26 in February 2018, e) 22 in March 2018, f) 25 in May 2018 and (g) 50 in July 2020.

PUBLICATIONS

For a Complete List of Hugo de Lasa’s publications, consult Google Academics Citations. https://scholar.google.com/citations?view_op=list_works&hl=en&user=iJfvhG4AAAAJ

Recent Publications by Hugo de Lasa

- Escobedo, S.; de Lasa, H.Photocatalysis for Air Treatment Processes: Current Technologies and Future Applications for the Removal of Organic Pollutants and Viruses. Catalysts, Commemorative Issue for Hugo de Lasa 2020, 10(9), 966, 1-39. https://doi.org/10.3390/catal10090966. IF: 3.52. MDPI. Cover of Special Issue.

- Escobedo, S.; Kong, S.; Lopez Zamora, S.; de Lasa, H. Synthetic Naphtha Recovery from Water Streams: Vapour‐Liquid–Liquid Equilibrium (VLLE) Studies in a Dynamic VL‐Cell Unit with High Intensity Mixing. Canadian Journal Chemical Engineering https://doi.org/10.1002/cjce.24120. IF: 1.61. J. Wiley.

- Kong, S.; Escobedo, S.; Lopez Zamora, S.; de Lasa, H. Phase Equilibrium in N-Octane/Water Separation Units: Vapor Pressures, Vapor and Liquid Molar Fractions. International Journal Chemical Reactor Engineering, Special Issue to Honor Dr. Orlando Alfano 2021, 1-11. https://doi.org/10.1515/ijcre-2021-0031. IF: 1.05. De Gruyter.

- López Zamora, S.; Escobedo, S.; Kong, S.; de Lasa, H. A Machine Learning Approach for Vapour-Liquid-Liquid and Vapour-Liquid Equilibrium of Paraffinic Aromatic Synthetic Naphtha/ Water Systems: Prediction of The Number of Phases. Canadian Journal Chemical Engineering May 10, IF: 1.61. J. Wiley. In Press.

- Lopez, Zamora S.; Escobedo, S.; Kong, S.; de Lasa, H. Thermodynamics and Machine Learning Based Approaches for Vapor–Liquid–Liquid Phase Equilibria in n-Octane/Water, as a Naphtha–Water Surrogate in Water Blends. Processes 2021, 9(3), 413,1-29. https://doi.org/10.3390/pr9030413. IF: 2.753.

- Rusinque, B.; Escobedo, S.; de Lasa, H. Hydrogen Production via Pd-TiO2Photocatalytic Water Splitting under Near-UV and Visible Light: Analysis of the Reaction Mechanism. Catalysts 2021, 11(3), 405, 1-25. https://doi.org/10.3390/catal11030405. IF: 3.52. MDPI.

- Sirivallop, A.; Escobedo, S.; Areerob, T.; de Lasa, H.; Chiarakorn Photocatalytic Conversion of Organic Pollutants in Air: Quantum Yields using a Silver/Nitrogen/TiO2 Mesoporous Semiconductor under Visible Light. Catalysts 2021,11(5), 529, 1-27. https://doi.org/10.3390/catal11050529. IF: 3.572. MDPI.

- Ahmed, I. ; de Lasa, H. CO2 Capture Using Chemical Looping Combustion from a Biomass-Derived Syngas Feedstock: Simulation of a Riser-Downer Scaled-Up Unit. Industrial & Engineering Chemistry Research 2020, 59(15), 6900–6913. https://doi.org/10.1021/acs.iecr.9b05753. IF: 3.573. Am. Chem. Soc.

- Ahmed, I. ; H. de Lasa, H. Syngas Chemical Looping Combustion Using a Highly Performing Fluidizable Oxygen Carrier. Catalysis Today2020, Vol. 343, 63-71. https://doi.org/10.1016/j.cattod.2019.01.011. IF: 4.66. Elsevier.

- Calzada, A.; Gonzalez, S.; Sanchez, A.; de Lasa, H.; Serrano, B. Ru-Promoted Ni/Al2O3 Fluidized Catalyst for Biomass Gasification. Catalysts, Commemorative Issue for Hugo de Lasa 2020, 10(3), 316, 1-17. https://doi.org/10.3390/catal10030316. IF: 3.572. MDPI.

- Cordoba-Perez, M.; de Lasa, H. CO2-Derived Carbon Capture and Photon Absorption Efficiency by Microalgae in Novel PhotoBioCREC. Industrial & Engineering Chemistry Research 2020, 59(33), 14710-14716. https://doi.org/10.1021/acs.iecr.0c02319. IF: 3.573. Am. Chem. Soc.

- Ibarra, A.; Palos, R.; Arandes, J.; Olazar, M.; Bilbao, J.; de Lasa, H. Synergy in the Cocracking under FCC Conditions of a Phenolic Compound in the Bio-Oil and a Model Compound for Vacuum Gasoil. Industrial & Engineering Chemistry Research2020, 59(17), 8145-8154. https://doi.org/10.1021/acs.iecr.0c00869. IF: 3.573. Am. Chem. Soc.

- Lopez Zamora, S.; de Lasa, H. A Mid-Infrared Region (MIR) Lumped Group Contribution Based Method for Monitoring Light Gases and Gasolines in Fluid Catalytic Cracking. Chemical Engineering Science 2020, Vol. 212, 115324, 1-11. https://doi.org/10.1016/j.ces.2019.115324. IF: 3.871. Elsevier.

- Medina, Pedraza C.; de Lasa, H.Cluster Acceleration and Stabilization in a Downflow Circulating Fluidized Bed Unit. Industrial & Engineering Chemistry Research 2020, 59(27), 12360-12370. https://doi.org/10.1021/acs.iecr.0c01397. IF: 3.573. Am. Chem. Soc.

- Rostom, S.; de Lasa, H.Propane Oxidative Dehydrogenation on Vanadium-Based Catalysts under Oxygen-Free Atmospheres. Catalysts, Commemorative Issue Hugo de Lasa 2020, 10(4), 418, 1-24. https://doi.org/10.3390/catal10040418. IF: 3.52. MDPI.

- Rusinque, B. ; Escobedo, S.; de Lasa, H. Photoreduction of Pd-Doped Mesoporous TiO2 Photocatalyst for Hydrogen Production under Visible Light. Catalysts Commemorative Issue Hugo de Lasa 2020, 10(1), 74, 1-24. https://doi.org/10.3390/catal10010074. IF: 3.52. MDPI.

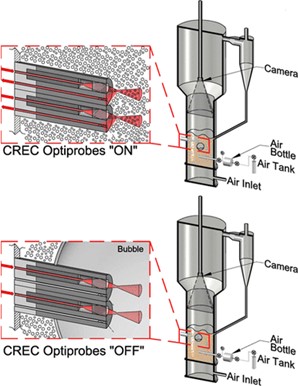

- Torres, Brauer N.; Serrano, B.; de Lasa, H.Single-Bubble Dynamics in a Dense Phase Fluidized Sand Bed Biomass Gasification Environment. Industrial & Engineering Chemistry Research 2020, 59(13), 5601-5614. https://doi.org/10.1021/acs.iecr.9b05674. IF: 3.37. Am. Chem. Soc. Cover of the Issue.

- Torres, C.; Rostom, S.; de Lasa, H.An Eco-Friendly Fluidizable FexOy/CaO-γ-Al2O3 Catalyst for Tar Cracking during Biomass Gasification. Catalysts Commemorative Issue Hugo de Lasa 2020, 10(7), 806, 1-27. https://doi.org/10.3390/catal10070806. IF: 3.520. MDPI.

- Ahmed, I.; de Lasa, H.110th Anniversary- Kinetic Model for Syngas Chemical Looping Combustion Using a Nickel-Based Highly Performing Fluidizable Oxygen Carrier. Industrial & Engineering Chemistry Research 2019, 58(8), 2801-2811. https://doi.org/10.1021/acs.iecr.8b05880. IF: 573. Am. Chem. Soc.

- Alkhlel, A.; de Lasa, H. Catalyst/Feedstock Ratio Effect on FCC Using Different Catalysts Samples. Catalysts 2019, 9(6), 542, 1-15. https://doi.org/10.3390/catal9060542. IF: 3.520. MDPI.

- Escobedo, S.;Rusinque, B.; de Lasa H. Photochemical Thermodynamic Efficiency Factors (PTEFs) for Hydrogen Production Using Different TiO2 Photocatalysts.Industrial & Engineering Chemistry Research 2019, 58(49), 22225-22235. https://doi.org/10.1021/acs.iecr.9b05086. IF: 573. Am. Chem. Soc.

- Rostom, S.; de Lasa, H. Downer Fluidized Bed Reactor Modeling for Catalytic Propane Oxidative Dehydrogenation with High Propylene Selectivity. Chemical Engineering and Processing – Process Intensification 2019, Vol. 137, 87-99. https://doi.org/10.1016/j.cep.2019.02.002. IF: 3.096. Elsevier.

- Rusinque, B.; Escobedo S.; de Lasa, H. Photocatalytic Hydrogen Production Under Near-UV Using Pd-Doped Mesoporous TiO2 and Ethanol as Organic Scavenger. Catalysts Special Issue on Photocatalysts by Invitation 2019, 9(1), 33, 1-22. https://doi.org/10.3390/catal9010033. IF: 3.082.

- Torres, C.; Urvina, L.; de Lasa, H. A Chemical Equilibrium Model for Biomass Gasification. Application to Costa Rica Pulp Transformation Unit. Biomass and Bioenergy 2019, Vol. 123, 89-103. https://doi.org/10.1016/j.biombioe.2019.01.025. IF: 3.358.

- Alhkel, A.;de Lasa, H. Catalytic Cracking of Hydrocarbons in a CREC Riser Simulator Using a Y Zeolite-Based Catalyst: Assessing the Catalyst/Oil Ratio Effect. Industrial & Engineering Chemistry Research 2018, 57(41), 13627-13638. https://doi.org/10.1021/acs.iecr.8b02427. IF: 2.84. Am. Chem. Soc.

- Bastos, A.; Torres, C.; Mazumder, A.; de Lasa, H.CO2 Biomass Fluidized Gasification: Thermodynamics and Reactivity Studies. Canadian Journal Chemical Engineering Special Issue to Honor Dr. Belkacemi 2018, 96(10), 2176-2184. https://doi.org/10.1002/cjce.23316. IF: 1.265. J. Wiley.

- Lopez Zamora, S.; Alkhlel, A.; de Lasa, H.Monitoring the Progress of Catalytic Cracking for Model Compounds in the Mid-Infrared (MIR) 3200–2800 cm−1 Range. Chemical Engineering Science 2018, 192, 788-802. https://doi.org/10.1016/j.ces.2018.08.021. IF: 3.871. Elsevier.

- Mazumder, A.; de Lasa, H. Steam Gasification of a Cellulosic Biomass Surrogate Using a Ni/La2O3-γAl2O3 Catalyst in a CREC Fluidized Riser Simulator. Kinetics and Model Validation. Fuel 2018, 216, 101-109. https://doi.org/10.1016/j.fuel.2017.11.074. IF: 4.601. Elsevier.

- Rostom, S.; de Lasa, H.High Propylene Selectivity via Propane Oxidative Dehydrogenation Using a Novel Fluidizable Catalyst: Kinetic Modeling. Industrial & Engineering Chemistry Research 2018, 57(31), 10251-10260. https://doi.org/10.1021/acs.iecr.8b01891. IF: 573. Am. Chem. Soc.

- Rostom, S.; de Lasa, H.Propane Oxidative Dehydrogenation Using Consecutive Feed Injections and Fluidizable VOx/γAl2O3 and VOx/ZrO2-γAl2O3 Catalysts. Industrial & Engineering Chemistry Research 2017, 56(45), 13109-13124. https://doi.org/10.1021/acs.iecr.7b01369. IF:573. Am. Chem. Soc.