Laser Material Processing and Microfabrication

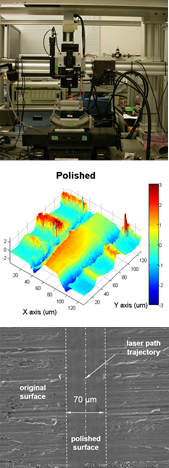

Laser material processing is a complex nonlinear process with numerous stochastic parameters related to the laser apparatus, optics and the material specimen. Researchers at Western and the National Research Council of Canada (NRCC) have developed nonlinear models to predict the level of pulse energy needed to create a dent with specific depth and diameter. Laser micromachining has also been used to rapidly construct mould masters for fabricating disposable polymeric micro-devices and laser micro-polishing (LµP) applications.

More recent research involves the development of electrically conductive graphene-based inks and novel fabrication processes for printing bioelectronic circuitry on a variety of mechanically flexible surfaces (e.g. polymers, paper, and biocompatible silk). Laser microfabrication techniques are used for material removal and thermally reducing graphene-oxide (GO) films to produce conductive microcircuit features. The work is supported, in part, by the Natural Sciences and Engineering Research Council (NSERC).

Collaborating Researchers: Drs. Suwas Nikumb and Evgueni Bordatchev (NRC-IMI, London)